Slitter rewinder-Advanced & High Efficiency

Introduction to Slitter rewinder

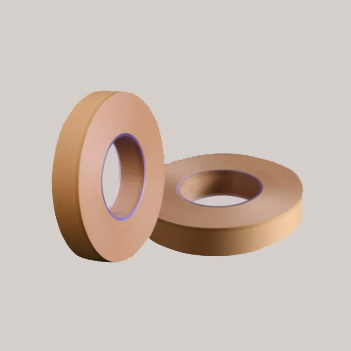

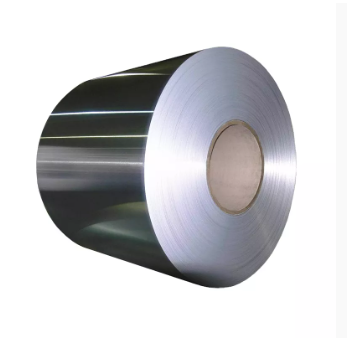

A slitter rewinder is a critical piece of equipment used in the converting industry, primarily for cutting and rewinding large rolls of material such as paper, film, foil, and textiles into smaller, manageable rolls. It operates by slitting the material into narrower widths while rewinding it into finished rolls.

Slitter rewinders are essential for precision cutting, efficient roll handling, and maintaining consistent material quality. They are commonly used in industries like packaging, printing, and flexible materials production. This equipment enhances productivity by ensuring high-speed operation, minimal waste, and accurate roll formation.

Product Advantages

Advanced Technology

High Efficiency

Precision Cutting

Reduced Waste

Flexibility

Improved Safety

Cost-Effective

Product Center

Technical Specifications

Heavy-Duty Dual Shaft Slitter Rewinder (A+B Shaft)

| Roller width | 1400-2400mm |

| Max.parent roll ia. | 1800mm |

| Max.rewind dia. | 1500mm |

| Slitting width | 50mm-2350mm |

| Rewind paper core dia. | 3"/6"Customized |

| Mechanical speed | 600m/min,(800m/min,1000m/min) |

| Power supply | 380V 50HZ 3PHASE |

| Total Power | 120KW |

| Machine weight | 12,000KG |

| Noise Level | <70 dB(A)+/-2dB(A) |

| Dimension | 6500*5400*2200mm |

| Compressed air | 6KG(not included) |

| Roller width | 1300-1700mm |

| Max.parent roll dia. | 1500mm |

| Max.rewind dia. | 850mm |

| Slitting width | 50mm-1650mm |

| Rewind paper core dia. | 3"/6"Customized |

| Mechanical speed | 600m/min,(700m/min,800m/min) |

| Power supply | 380V 50HZ 3PHASE |

| Total Power | 76KW |

| Machine weight | 8000KG |

| Noise Level | <70 dB(A)+/-2dB(A) |

| Dimension | 4200*4000*2100mm |

| Compressed air | 6KG(not included) |

Essential Dual Shaft Slitter Rewinder

| Roller width | 1300-1700mm |

| Max.parent roll dia. | 1200mm |

| Max.rewind dia. | 650mm |

| Slitting width | 50mm-1650mm |

| Rewind paper core dia. | 3"/6"Customized |

| Mechanical speed | 400m/min,(600m/min,700m/min,800m/min) |

| Power supply | 380V 50HZ 3PHASE |

| Total Power | 45KW |

| Machine weight | 4500KG |

| Noise Level | <200 dB(A)+/-2dB(A) |

| Dimension | 4200*4000*2100mm |

| Compressed air | 5KG(not included) |

Service

Frequently Asked Questions (FAQ)

Q: What is a slitter rewinder used for?

Q: How does a slitter rewinder increase efficiency?

Q: What materials can be processed by a slitter rewinder?

Q: How does a slitter rewinder ensure precision?

Q: Are slitter rewinders safe to use?

Q: How does a slitter rewinder reduce waste?

Related News

-

We are proud to announce that THAI KK, a leading manufacturer in Thailand's adhesive label industry, has officially launched their JUYOU SF-850 and expressed exceptional satisfaction with its performance. This successful implementation marks a significant breakthrough for JUYOU in the Southeast Asia

We are proud to announce that THAI KK, a leading manufacturer in Thailand's adhesive label industry, has officially launched their JUYOU SF-850 and expressed exceptional satisfaction with its performance. This successful implementation marks a significant breakthrough for JUYOU in the Southeast Asia -

Juyou Intelligent has deployed its Dual-Shaft Slitter Rewinder at Okil-Sato, a premier adhesive label manufacturer in Russia. This high-precision system enables non-stop conversion of label stocks, eliminating material waste during roll changes. With automatic tension control and 800m/min processing

Juyou Intelligent has deployed its Dual-Shaft Slitter Rewinder at Okil-Sato, a premier adhesive label manufacturer in Russia. This high-precision system enables non-stop conversion of label stocks, eliminating material waste during roll changes. With automatic tension control and 800m/min processing

Related Videos

Keep in touch with us

Tel

+86-769-82393739

+86-769-82395695

Sense: +8618221064536

Dale: +8618221060206

Address

No.7 Dajin Road, Xixi Liaobu Town, Dongguan, Guangdong, China